- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Top Metal Spinning Tools to Enhance Your Manufacturing Process in 2025

In the rapidly evolving manufacturing landscape of 2025, the role of metal spinning tools is becoming increasingly significant. These precision instruments not only enhance efficiency but also drive innovation in design and production processes. According to industry expert, Dr. Emily Carter, “The future of manufacturing lies in the ability to adapt and integrate advanced metal spinning tools that allow for customization and improved production rates.” This insight underscores the vital importance of investing in state-of-the-art technology to remain competitive in a market that demands both speed and quality.

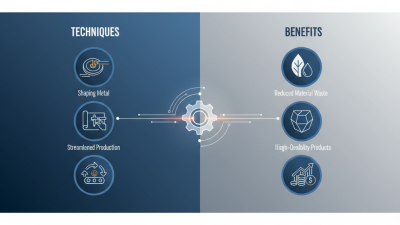

As manufacturers strive to optimize their processes, the demand for reliable and versatile metal spinning tools continues to rise. These tools not only facilitate the creation of complex shapes from metal sheets but also offer advantages such as reduced material waste and lower operational costs. With advancements in technology, such as automation and improved design features, metal spinning tools are poised to transform traditional manufacturing methods, enabling businesses to meet the challenges of an ever-changing industry with agility and precision.

The year 2025 presents unique opportunities for manufacturers who harness the potential of these innovative tools. By understanding the latest developments in metal spinning technology and incorporating them into their operations, manufacturers can enhance their productivity, reduce costs, and ultimately, improve their competitive edge in a global market. In this article, we will explore some of the top metal spinning tools available and their impact on the manufacturing process, ensuring that businesses are well-equipped for the future.

Table of Contents

[Hide]

Overview of Metal Spinning Tools and Their Importance in Manufacturing

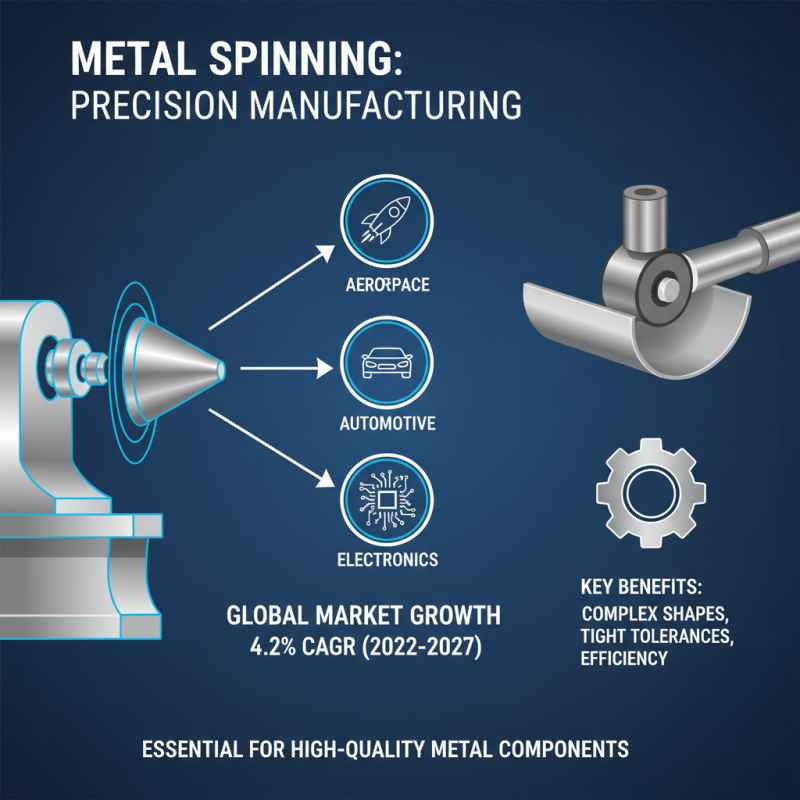

Metal spinning, a versatile manufacturing process, plays a crucial role in producing precision components for various industries such as aerospace, automotive, and electronics. According to a report by Research and Markets, the global metal spinning market is projected to grow at a CAGR of 4.2% from 2022 to 2027, highlighting the increasing demand for high-quality spun metal products. Metal spinning tools are essential in this process, as they enable manufacturers to create complex shapes and designs efficiently while maintaining tight tolerances.

The significance of advanced metal spinning tools cannot be overstated. These tools enhance the accuracy and repeatability of the spinning process, significantly reducing waste and production costs. A study published by the Journal of Manufacturing Science and Engineering found that employing state-of-the-art metal spinning tools can improve productivity by up to 30%. Additionally, the adoption of CNC (Computer Numerical Control) technologies in metal spinning tools allows for greater flexibility and customization, which is particularly beneficial in meeting the diverse needs of clients across various sectors. As manufacturers strive to improve operational efficiency and product quality in 2025, investing in high-performance metal spinning tools will remain a key factor in achieving these objectives.

Key Features to Look for in Modern Metal Spinning Tools

When selecting modern metal spinning tools for your manufacturing process, it's crucial to focus on several key features that enhance efficiency and precision. One of the primary attributes to consider is the tool's level of automation. Advanced tools often incorporate automated systems that streamline the spinning process, reduce manual intervention, and increase production rates. Look for features such as programmable settings that allow for quick adjustments and easy operation, which can significantly improve workflow and reduce downtime.

Another essential aspect is the material compatibility and flexibility of the tool. The best metal spinning tools are designed to handle a variety of metals, from aluminum to titanium, giving manufacturers the versatility needed for diverse applications. Additionally, assess the tool's durability and build quality, as robust construction will ensure long-lasting performance and resistance to wear and tear. Incorporating user-friendly controls and real-time monitoring systems can provide feedback on tool performance, enabling operators to make informed decisions that enhance product quality and consistency in the final output.

Top Metal Spinning Tools to Enhance Your Manufacturing Process in 2025 - Key Features to Look for in Modern Metal Spinning Tools

| Tool Type | Material Compatibility | Max Diameter (inches) | Power Source | Key Features |

|---|---|---|---|---|

| CNC Metal Spinner | Aluminum, Steel | 36 | Electric | High precision, Easy integration with CAD |

| Manual Metal Spinner | Copper, Brass | 24 | Manual | Cost-effective, Portable |

| Hydraulic Metal Spinner | Aluminum, Titanium | 48 | Hydraulic | High torque, Suitable for thick materials |

| Electric Metal Spinner | Steel, Nickel | 30 | Electric | Fast operation, User-friendly interface |

| Pneumatic Metal Spinner | Aluminum, Copper | 20 | Pneumatic | Compact design, Low maintenance |

Top Metal Spinning Tool Manufacturers to Consider in 2025

When considering metal spinning tools for your manufacturing needs in 2025, it is essential to explore the top manufacturers known for their innovation and quality. A comprehensive evaluation of these manufacturers reveals their commitment to advancing technology while keeping production efficiency at the forefront. Many leading manufacturers are integrating automation and smart technology into their tool designs, resulting in enhanced precision and speed during the metal spinning process.

Additionally, these manufacturers are focusing on providing customizable solutions that cater to the diverse requirements of modern manufacturing. They offer tools that can accommodate various materials, sizes, and production scales, ensuring that businesses can achieve optimal results regardless of their specific needs. By selecting reliable manufacturers that emphasize robust customer support and after-sales services, companies can enhance not only their production capabilities but also their overall operational efficiency in the competitive manufacturing landscape of 2025.

Emerging Technologies in Metal Spinning Tools for Enhanced Efficiency

The manufacturing landscape is rapidly evolving with the introduction of emerging technologies in metal spinning tools, set to reshape efficiency standards across the industry in 2025. These advancements are not limited to automation; they also incorporate artificial intelligence and machine learning algorithms to optimize production processes. By analyzing patterns and predicting machine failures, these technologies decrease downtime and enhance overall productivity, allowing manufacturers to maintain consistent quality and speed in their operations.

In addition to AI, the integration of advanced materials and smart sensors is transforming traditional metal spinning techniques. These sensors enable real-time monitoring of the spinning process, providing instant feedback on parameters such as pressure and temperature. This data not only facilitates immediate adjustments but also allows for predictive maintenance, ensuring the longevity of the equipment. Moreover, new materials that are lighter and more durable are being developed, which improve the efficiency of the spinning process and reduce material waste. As manufacturers adopt these innovative tools, they stand to gain a significant competitive advantage by increasing their operational efficiency and product quality in an increasingly demanding marketplace.

Best Practices for Using Metal Spinning Tools in Manufacturing Processes

Effective use of metal spinning tools is crucial for optimizing manufacturing processes. To achieve optimal results, it is essential to start with proper training for operators. Understanding the mechanics of metal spinning—including the interplay of speed, pressure, and tool angle—can help operators manipulate the machinery more efficiently. Regular practice and thorough knowledge of the equipment can lead to improved precision and reduced waste, ensuring that products meet quality standards without unnecessary rework.

Another best practice involves meticulous maintenance of spinning tools. Regular inspections and timely replacements of worn parts are vital to maintaining performance levels. Additionally, keeping the workspace organized and ensuring that tools are readily accessible can enhance workflow efficiency. Implementing these practices not only prolongs the lifespan of equipment but also fosters a safe working environment, minimizing the risk of accidents and enhancing overall productivity in the metal spinning operation.

Top Metal Spinning Tools to Enhance Your Manufacturing Process in 2025

Related Posts

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

How to Effectively Use Spin Forming Metal Techniques in Manufacturing

-

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

-

2025 Top 5 Pipe Roll Forming Machines You Need to Know

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits