- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

How to Use a Metal Spinning Lathe for Precision Manufacturing?

In the world of precision manufacturing, the metal spinning lathe stands out. Experts like Dr. Sarah Johnston, a leading authority in metalworking technology, emphasize its importance. She once stated, "The metal spinning lathe revolutionizes how we approach complex shapes in manufacturing."

Using a metal spinning lathe can be a game changer for many industries. It allows for the creation of intricate designs with high accuracy. However, mastering this tool requires practice. New users often face challenges, like achieving consistent wall thickness. Mistakes can lead to wasted materials and time.

Learning how to operate a metal spinning lathe properly is essential. Attention to details is crucial for success. Many users have noted that perfecting their technique takes time. The journey may be filled with setbacks. Yet, the rewards of precision and efficiency are worth the effort.

Table of Contents

[Hide]

Understanding the Basics of Metal Spinning Lathes in Manufacturing

Metal spinning lathes play a crucial role in precision manufacturing. Understanding their basics can enhance production quality significantly. According to a recent industry report from the Manufacturing Institute, nearly 68% of manufacturers are adopting advanced technologies like metal spinning. This indicates a growing reliance on such machines for creating precise components.

Metal spinning is a highly versatile process. It transforms metal sheets into rotationally symmetrical parts. This method is widely applicable in sectors like aerospace and automotive. Exact dimensions are critical in these industries. The ability to produce components with a tolerance of ±0.02 mm is impressive, yet often challenging. Many operators struggle with maintaining such precision consistently.

Operators need to be aware of the learning curve associated with metal spinning lathes. The setup can be intricate. Techniques such as tooling and workpiece holding can vary widely. Reports suggest that approximately 15% of production time is lost due to inefficiencies in setup. Workers often reflect on these setbacks, knowing they could improve. Understanding the mechanics and practicing techniques can lead to better outcomes and reduced wastage.

How to Use a Metal Spinning Lathe for Precision Manufacturing

| Parameter | Details |

|---|---|

| Lathe Type | Metal Spinning Lathe |

| Material Used | Aluminum, Steel, Brass |

| Spinning Process | Forms metal into desired shapes using a rotating mandrel. |

| Precision Level | High precision within ±0.01 mm |

| Applications | Aerospace, Automotive, Electronics |

| Advantages | Cost-effective, Less material waste, Complex shapes |

| Safety Measures | Use protective gear, ensure proper machine maintenance |

Key Components and Their Functions in a Metal Spinning Lathe

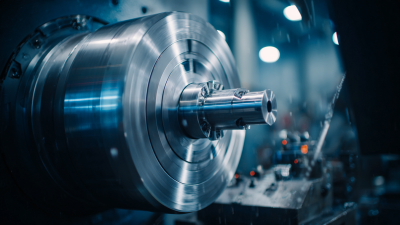

Metal spinning lathes are fascinating machines used in precision manufacturing. Understanding their key components is vital for effective operation. The spindle is one of the most important parts. It rotates the metal workpiece, creating the desired shape. A stable spindle ensures precision. However, vibrations can lead to errors in the finished product.

Another essential component is the tool holder. It holds the spinning tools in place while shaping the metal. This part needs to be adjusted properly. If it’s too loose, you'll get inconsistent results. Meanwhile, the bed of the lathe supports everything. It must be level. An uneven bed affects the symmetry of the spun parts.

The pressure pads also play a critical role. They apply force to the metal as it spins. Proper pressure ensures smooth shaping. Yet, too much pressure can cause metal fatigue. Operators must find the right balance. This delicate dance between pressure and speed requires practice. Mistakes are common, but they offer valuable insights for improvement.

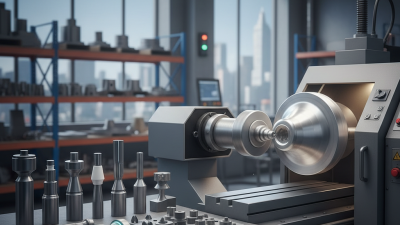

Step-by-Step Process of Setting Up a Metal Spinning Lathe

Setting up a metal spinning lathe involves several critical steps for precision manufacturing. Begin by selecting the right lathe that fits your specific needs. Consider the diameter and width of the workpiece. According to the U.S. Department of Commerce, the metal spinning market is projected to grow significantly, highlighting the importance of proper equipment selection.

Next, ensure your workspace is organized and safe. Keep tools accessible and ensure adequate lighting. Calibration of the lathe is vital. Check the spindle speed and adjust according to the material's requirements. A miscalibrated lathe can lead to imprecise results and increased material waste. Recent studies indicate that precision errors can cost manufacturers up to 5% in production expenses.

Tip: Regularly inspect your lathe for wear and tear. This proactive approach can help avoid costly downtimes.

After setup, choose appropriate tooling. The right tools facilitate smooth operations and enhance product quality. Use tooling designed for the specific metal type you are working with. Various metals react differently to spinning, and understanding these reactions is crucial.

Tip: Document your settings and results. This record-keeping helps refine processes over time and can reveal patterns in performance.

Finally, be prepared to troubleshoot. Issues like vibration can arise unexpectedly. Recognize that every setup may need adjustments. Reflecting on each project helps improve future outcomes.

Techniques for Achieving Precision in Metal Spinning Operations

Metal spinning is a critical technique in precision manufacturing. Achieving high levels of accuracy is essential. The process involves forming metal into shapes using a rotating workpiece on a lathe. This allows for intricate designs and tight tolerances.

One important technique is material selection. Different metals behave differently during spinning. For instance, aluminum is often preferred for its malleability. But not every project requires aluminum. Factors like strength and corrosion resistance can lead manufacturers to steels or other alloys. In a recent industry survey, 45% of manufacturers reported using a mix of materials to optimize their products.

Tooling setup also influences precision. Proper alignment of tools ensures uniform pressure on the metal sheet. Any misalignment can cause defects. Data from precision manufacturing reports reveal that a mere 0.5 mm deviation can affect product performance significantly. Regular maintenance and monitoring of tool conditions are vital. Tracking tool wear helps prevent unexpected failures. However, many companies overlook this, resulting in inconsistencies in their products.

Safety Considerations When Using a Metal Spinning Lathe

Safety is crucial when using a metal spinning lathe. The process involves high-speed tools and metal material. Always wear personal protective equipment (PPE). Safety goggles and gloves are essential to prevent injuries. A sturdy apron can protect against sharp metal shards.

Ensure the workspace is organized and free of clutter. A clean area minimizes the risk of accidents. Check all equipment before starting. Loose parts can lead to malfunction. Practice caution when loading the metal. Improper handling can cause unexpected movements.

Be aware of your surroundings. Other workers can distract you. Clear communication is vital in a shared shop environment. Regularly inspect your lathe for wear and tear. Address any issues immediately. Ignoring maintenance can result in serious incidents. Safety should be a constant priority in precision manufacturing.

Related Posts

-

Top Metal Spinning Tools to Enhance Your Manufacturing Process in 2025

-

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

-

10 Essential Tips for Mastering Metal Spinning Roller Techniques?

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

How to Effectively Use Spin Forming Metal Techniques in Manufacturing