- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Why Choose a Steel Roll Former for Your Manufacturing Needs?

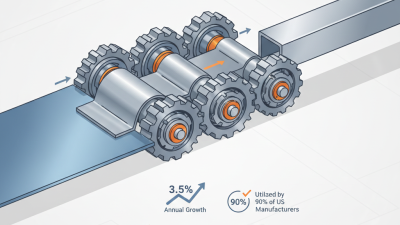

The manufacturing industry is experiencing a significant transformation, with an increasing demand for efficient and precise production methods. Among the array of innovative technologies, the steel roll former stands out as a vital asset for manufacturers seeking to enhance their operational capabilities. According to a report by Grand View Research, the global roll forming market size is estimated to reach USD 5.04 billion by 2025, growing at a CAGR of 5.5%. This growth underscores the rising reliance on automated forming processes, particularly in industries such as construction, automotive, and appliance manufacturing.

Using a steel roll former not only improves production efficiency but also ensures consistency and precision in the finished products. Numerous studies indicate that manufacturers employing advanced roll forming technologies can achieve up to a 30% reduction in material waste compared to traditional fabrication methods. Furthermore, the versatility of steel roll forming systems allows companies to cater to diverse applications, ranging from structural components to intricate designs, without compromising on quality or performance. As market demands continue to evolve, the adoption of steel roll formers becomes a strategic move for businesses aiming to maintain competitive advantage in the ever-challenging manufacturing landscape.

Table of Contents

[Hide]

Key Advantages of Steel Roll Formers in Manufacturing

Steel roll forming is increasingly recognized as a pivotal technology in modern manufacturing, offering a range of key advantages that enhance productivity and efficiency. One of the primary benefits is the ability to produce uniform and precise components with minimal waste. According to industry reports, manufacturers can achieve up to 30% material savings compared to traditional manufacturing methods. This is largely due to the continuous process of steel roll forming, which allows for high-volume production without the interruption or scrap typically associated with other forming techniques.

Moreover, steel roll formers are known for their versatility and adaptability in various applications. A report by the Fabricators & Manufacturers Association International highlights that over 65% of manufacturers have integrated roll forming into their processes due to its capability to accommodate different materials and product designs. This adaptability not only facilitates rapid design changes but also supports the production of complex shapes that meet specific application requirements. As industries shift towards more sustainable practices, the reliance on steel roll forming for efficient production processes is anticipated to grow, with many experts forecasting an increase in the use of this technology across diverse manufacturing sectors.

The Versatility of Steel Roll Forming for Various Industries

Steel roll forming offers remarkable versatility that caters to a wide array of industries, from construction to automotive manufacturing. By transforming flat steel sheets into tailored shapes and profiles, this process allows manufacturers to produce components that meet specific design and functional requirements. The seamless integration of steel roll forming in various applications ensures that businesses can leverage its efficiency to save time and reduce waste while maintaining high-quality standards.

In the construction sector, for instance, steel roll forming is utilized to create roofing materials, wall panels, and support structures. The ability to customize profiles means that manufacturers can respond quickly to market demands, producing components that fit unique architectural designs. Similarly, in the automotive industry, roll-formed steel components contribute to lighter yet stronger vehicle structures, enhancing performance while complying with safety regulations. This adaptability not only boosts the productivity of manufacturing processes but also opens doors for innovation in product design across diverse sectors.

Cost-effectiveness: How Steel Roll Formers Save Money

Steel roll formers have become a preferred choice for manufacturers looking to enhance efficiency while reducing operational costs. These machines are designed to produce standardized metal profiles at high speeds, significantly reducing labor costs associated with manual fabrication methods. The automated processes allow for continuous production, minimizing downtime and waste during the manufacturing cycle, which translates into substantial savings over time.

Additionally, the precision and consistency offered by steel roll formers lead to fewer defects and the need for rework, which can be costly and time-consuming. By investing in a steel roll former, manufacturers benefit from lower material waste and can take advantage of less expensive raw materials, ultimately improving their bottom line. This combination of efficiency, reduced labor costs, and waste minimization makes steel roll formers an attractive solution for businesses aiming to streamline their operations while maintaining quality and cost-effectiveness in their production processes.

Quality and Precision: Enhancing Production Standards with Steel

When it comes to modern manufacturing, quality and precision are paramount. Utilizing a steel roll former is one of the most effective ways to enhance production standards. Steel roll forming not only ensures that products meet strict specifications but also improves the durability and reliability of the manufactured components. The consistent shaping of steel through this process results in greater uniformity, which is vital for industries that demand exact measurements and high-quality finishes.

Moreover, steel roll forming provides flexibility in production. With the ability to create complex profiles, manufacturers can optimize their designs while maintaining high standards of quality. This combination of precision engineering and material strength enables companies to produce parts that withstand rigorous demands. By employing a steel roll former, businesses can significantly reduce material waste and improve efficiency, all while ensuring that their products maintain a superior level of craftsmanship that meets the needs of their clients.

Why Choose a Steel Roll Former for Your Manufacturing Needs?

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Durability | Steel roll formers are built to withstand continuous operation. | Reduced need for maintenance, longer lifespan. | Construction materials, roofing panels. |

| Precision | Provides consistent thickness and dimensional accuracy. | Higher quality products, minimal waste. | HVAC components, metal framing. |

| Efficiency | Rapid production speeds without sacrificing quality. | Increased output, reduced labor costs. | Automotive parts, shelves, brackets. |

| Versatility | Can produce a wide variety of profiles and shapes. | Adaptable to multiple projects and industries. | Construction, agriculture, furniture. |

Maintenance and Longevity of Steel Roll Forming Equipment

When considering the longevity and reliability of steel roll forming equipment, regular maintenance is paramount. Steel roll formers are designed for heavy-duty performance; however, without proper care, their efficiency can diminish over time. Regular inspections should include checking for wear and tear on rollers and other moving parts, as well as ensuring that the machine is properly lubricated. This proactive approach not only enhances performance but also extends the operational life of the equipment.

**Tips:** Make it a routine to clean the equipment after each use to remove debris and prevent rusting. Additionally, establish a maintenance schedule based on the machine's usage and consult the manufacturer’s guidelines for optimal care practices.

By focusing on maintenance practices like replacing worn components and promptly addressing any mechanical issues, manufacturers can reduce downtime and avoid costly repairs. A well-maintained steel roll former will not only provide consistent output quality but also ensure that your operations run smoothly for years.

**Tips:** Keep a logbook of maintenance activities to track performance and identify recurring issues. This documentation can also be invaluable when assessing machine needs for future upgrades or replacements.

Why Choose a Steel Roll Former for Your Manufacturing Needs?

Related Posts

-

10 Essential Tips for Mastering Metal Flow Forming Techniques

-

How to Use Flow Forming Steel for Maximum Strength and Durability

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry

-

Understanding the Roll Forming Process: Benefits and Applications Explained

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques